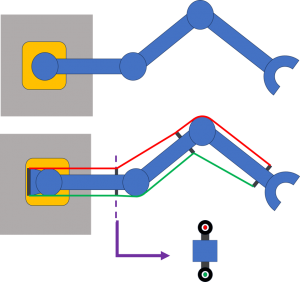

When a manipulator is deployed in hazardous environments, withstand failures without compromising its ability to perform its tasks is highly desirable. Therefore, fault-tolerance structures are designed to ensuring dependability of the manipulator. Most previous studies of fault-tolerant manipulators have focused on locked-joint failures, but we address free-swinging failures. To improve manipulator fault tolerance under free-swing failures, we developed a new structure that adds artificial tendons (elastic strings) along both sides of the manipulator segments . These tendons generate torques at the joints when a failure occurs, which allows the manipulator to maintain its ability to move in some parts of the workspace (fault-tolerant Workspace, FTWS). We carry out computer simulations and the results show that the new-designed manipulator works better than locked-joint fault-tolerant manipulators after a fault occurs. Further research is still ongoing.

. These tendons generate torques at the joints when a failure occurs, which allows the manipulator to maintain its ability to move in some parts of the workspace (fault-tolerant Workspace, FTWS). We carry out computer simulations and the results show that the new-designed manipulator works better than locked-joint fault-tolerant manipulators after a fault occurs. Further research is still ongoing.

Division of Mechanics, Beijing Computational Science Research Center